Technical parameters

Bottle feeding turntable

1. Suitable specification: according to the sample provided by the customer

2. Rotary table diameter: 900mm

3. Height from the table top to the ground: 750mm

4. Power supply: 220V, 140W, 50Hz, single phase

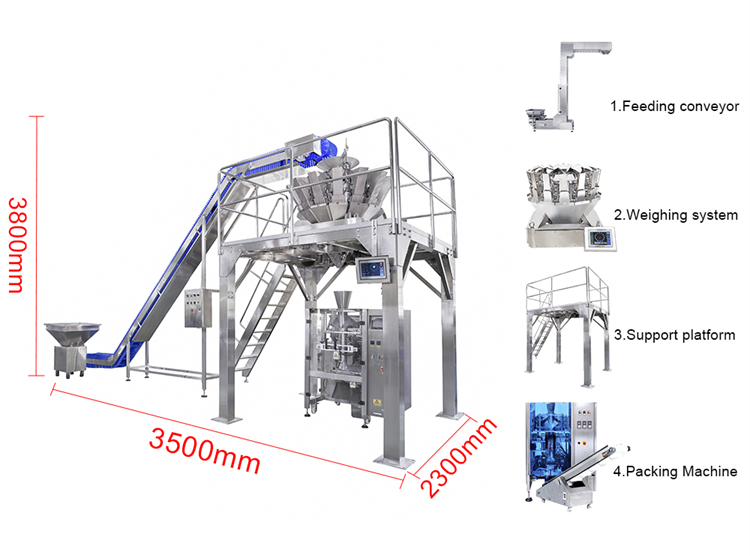

Multi head granule weigher filling machine

1. Single weighing range: 10-1000g

2. The maximum weight is 6500g

3. The average error of single bag is 0.2-0.7g

4. Weighing accuracy range: 0.1-1.5g

5. Maximum weighing speed: 1200 bottles / hour (1000g)

6. Hopper capacity 2500ml

7. Hopper form: double row memoryless bucket

8. Driving mode: stepping motor

9. 99 preset products

10. Number of multi head scales: 14

11. Number of filling heads: 1

Chuck type (with vibration) granule filling machine

(during filling, there will be different degrees of leakage due to the particularity of materials)

1. Number of filling heads: 1

2. Suitable bottle type: according to the customer's sample

3. Filling capacity: according to the customer's sample (the chuck needs to be replaced and the machine part needs to be adjusted for different bottle types)

4. Filling form: multi head scale filling

5. Production speed: 30 bottles / min

6. Overall power: About 1.5kw

7. Air pressure: 0.6-0.8mpa

8. Power supply: AC220V, 50 / 60Hz, single phase

9.14 the head scale is additionally equipped with a foot filling function and an independent filling hopper (suitable for filling 1000g)

Desiccant packer

1. The applicable object is based on the customer model

2. The size of desiccant bag is 15-30x40-60mm

3. Production capacity: 30 bottles / min

4. Power supply voltage 220V / 50Hz

5. Overall dimension 650 × six hundred and fifty × 1360mm

6. Weight: 100kg

Chuck can sealer

1. Applicable product range: samples provided by customers (chuck needs to be changed for different specifications)

2. Applicable bottle cap diameter: samples provided by customers (accessories need to be adjusted for different specifications)

3. Lower cover form: pneumatic automatic lower cover

4. Can sealing form: single head claw cover

5. Production capacity: 30 bottles / min

6. Main motor: 370W

7. Air pressure: 0.6-0.8mpa

Automatic clamping and rotating capping machine

1. Cover arrangement method: lift the mechanism cover, and the suction cup automatically puts the cover (the guide rail needs to be replaced for different specifications)

2. Suitable specification: according to the sample provided by the customer

3. Screw cap form: clip on screw cap (mechanical parts need to be adjusted for different specifications)

4. Speed: 30 bottles / minute

5. Overall power: 800W

6. Air pressure: 0.6-0.8mpa

Vertical round bottle labeling machine

1. Applicable product range: according to the samples provided by customers

2. Applicable label range: according to the sample provided by the customer

3. Labeling position: round bottle circumference

4. Labeling accuracy: ± 1 (excluding shape error)

5. Production capacity: 30 bottles / min

6. Voltage: 220V

7. Power: About 800W